more fiddling with the fabber

- Posted by darkeye on May 20th, 2008 filed in log, mechanics

- Comment now »

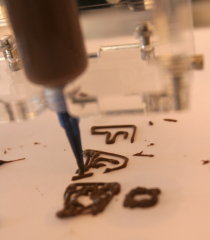

Today we’ve done some more fiddling with the fabber, after exchaning some e-mails with Frank Oxener from the Texel FabLab. First the tip of the syringe hat to be clean of dried-up Nutella. Frank’s suggestion was to use a lower pressure for pushing out the Nutella, so that the plug will not push through it. Using a video link to FabLab Norway, we also found out that they were using chocolate to do some fabbing themselves. I also thought – if one can create a syringe that one can keep at constant temperature, one could really use well tempered chocolate for fabbing.

So, we tried again, but it didn’t work. After some annoyance and investigation, it seemed that the 3D representation of the fabber inside the fabber software was quite contradictory. After some investigation, it turned out that 3 of the 4 axes were connected in reverse – even though we followed the documentation properly. Well, anyway, after connecting the stepper motor cables to the control electronics, at least the 3D representation seems to be OK.

And them editing and playing about with the tool description file, and it seems to be working…

Though the thing is, that the fabber stops in between the process, ‘waiting’ for something. Well, I guess there’s still some stuff to figure out…

Leave a Comment

You must be logged in to post a comment.